Lijenereithara tsa naetrojene li bohlokoa bakeng sa tlhahiso ea indasteri ea sejoale-joale, li tšehetsa lits'ebetso ho tloha paballong ea lijo ho isa tlhahisong ea lisebelisoa tsa elektroniki. Ho eketsa nako ea tšebeletso ea tsona ha se feela senotlolo sa ho fokotsa litšenyehelo tsa ts'ebetso empa hape ke habohlokoa bakeng sa ho qoba ho emisoa ho sa lebelloang ha tlhahiso. Sena se itšetlehile ka tlhokomelo e hlophisitsoeng le e tsitsitseng:

Taba ea pele, nkela lifilthara le li-desiccant sebaka khafetsa: Lifilthara tsa pele (bakeng sa lerōle le mahoashe le moholi oa oli) li lokela ho fetoloa likhoeli tse ling le tse ling tse 3-6, ha lifilthara tse nepahetseng (tse tšoasang likaroloana tse tšesaane) le li-desiccant (tse monyang mongobo) li hloka ho nkeloa sebaka likhoeli tse ling le tse ling tse 6-12—li lokisoa ho latela tšilafalo ea moea sebakeng seo (mohlala, li-workshop tse nang le lerōle li hloka liphetoho tse ngata khafetsa). Likarolo tsena li sebetsa e le "tšitiso ea pele" ea sistimi; ho hlokomoloha ho nkeloa sebaka ho ka lumella litšila ho kena toreng ea ho monya, ho koala li-sieve tsa limolek'hule (ho fokotsa bohloeki ba naetrojene ka 5%-10% ha nako e ntse e ea) kapa ho senya tšepe ea ka hare ea tora, ho khutsufatsa bophelo ba lisebelisoa ka lilemo.

Sa bobedi, ho lekanya ho ntsha metsi kgwedi le kgwedi le ho lekanya bohloeki: Sekarola metsi botlaaseng ba jenereithara se bokella metsi a kopantseng letsatsi le letsatsi—ho ntsha metsi ka botlalo kgwedi le kgwedi ho thibela metsi ho kopana le oli e tlotsang (e leng se tla fokotsa bokgoni ba ho tlotsa le ho baka ho tsofala ha dibearing) le diphaephe tsa tshepe tse rusang. Sebedisa setsebi sa ho lemoha bohloeki ba naetrojene bakeng sa ho lekanya kgwedi le kgwedi; haeba bohloeki bo wela ka tlase ho maemo a hlokahalang (mohlala, 99.99% bakeng sa di-elektroniki), lokisa nako ya potoloho ya ho monya metsi kapa o nkele sebaka di-sieve tsa dimolekhule tse tsofetseng kapele ho qoba ho imetswa ka nako e telele, e leng se sitisang compressor ya moya.

Sa boraro, laola mocheso le mongobo o tikolohong: Boloka tikoloho ea mosebetsi ea 5°C-40°C le mongobo o lekanyelitsoeng ≤85%. Lithempereichara tse ka tlase ho 5°C li teteanya oli e tlotsang, li eketsa mojaro le tšebeliso ea matla ea compressor ea moea ka 10%-15%; ka holimo ho 40°C, bokhoni ba ho monya moea ka sefe ea limolek'hule bo theoha haholo. Mongobo o phahameng (o fetang 85%) o ka etsa hore likarolo tsa motlakase tse kang liphanele tsa taolo li be le potoloho e khuts'oane—kenya li-air conditioner kapa li-dehumidifier libakeng tse mongobo (mohlala, sehleng sa lipula sa boroa ho Chaena) ho sireletsa likarolo tse bonolo.

Ea bone, ho tlotsa ka nako e loketseng le ts'ebetso e tloaelehileng: Tlotsa likarolo tse tsamaeang (mohlala, li-bearings tsa compressor ea moea, li-valve stems) likhoeli tse ling le tse ling tse 3 u sebelisa oli ea ho tlotsa e khothalletsoang ke moetsi—latela tekanyo ea bukana (e ngata haholo e baka ho lutla ha oli, e baka khohlano e omileng). Koetlisa basebetsi ho khomarela mekhoa ea ho qala/ho emisa: mohlala, le ka mohla u se ke ua tima jenereithara ka tšohanyetso nakong ea ts'ebetso e phahameng, kaha sena se baka litšitiso tsa khatello tse senyang li-valve. Hammoho, mehato ena e ka eketsa bophelo ba jenereithara ka mokhoa o tsitsitseng ka ~20%.

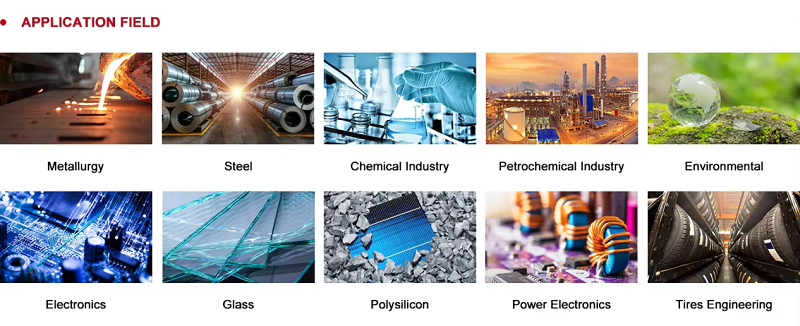

Lijenereithara tsa naetrojene li sebeletsa mafapha a fapaneng a tlhokeho e phahameng: lijo (liphutheloana tse fetotsoeng tsa sepakapaka bakeng sa lijo tse bobebe le nama e foreshe, nako ea ho boloka e imenne habeli), lisebelisoa tsa elektroniki (99.999% naetrojene e hloekileng haholo bakeng sa ho tjheseletsa chip, ho thibela ho oxidation ea pin), lik'hemik'hale (tšireletso e sa sebetseng bakeng sa liketso tse ka tukang joalo ka ho kopanya polyurethane, ho qoba likotsi tsa mollo), meriana (ho omisa lithethefatsi le ho koala libotlolo, ho netefatsa hore ha ho mongobo o amang botsitso ba lithethefatsi), tšepe (phekolo ea mocheso e tletseng naetrojene bakeng sa tšepe, ho thibela ho oxidation ea bokaholimo), likoloi (ho phahama ha mabili, ho fokotsa ho lutla ha moea ka 30%), esita le ho etsa veine (ho eketsa naetrojene libareleng tsa veine, ho boloka tatso ka ho tlosa oksijene).

Lijenereithara tsa naetrojene tsa PSA li feta litsamaiso tsa setso tsa karohano ea moea tse nang le cryogenic bakeng sa likhoebo tse nyane le tse mahareng, ka melemo e hlakileng: Li na le sebaka se senyenyane (2-5).㎡bakeng sa yuniti ea 50Nm³/h khahlanong le mashome/makholo a㎡bakeng sa litsamaiso tsa cryogenic, tse kenngoang libakeng tse nyane tsa mosebetsi), matsete a pele a tlase ka 30%-50% (ha ho hlokahale meralo ea motheo ea ho pholisa e kholo), ho qala ka potlako (metsotso e 30 ho fihlela bohloeki bo lekantsoeng khahlano le lihora tse 24-48 tsa ho pholisa pele ho nako bakeng sa litsamaiso tsa cryogenic, tse loketseng tlhahiso ea sehlopha), tlhahiso e tenyetsehang (fetola phepelo ea naetrojene ho latela tlhoko ea nako ea sebele, ho boloka matla a 15%-20% khahlano le ts'ebetso e felletseng ea litsamaiso tsa cryogenic feela), le tlhokomelo e bonolo (basebetsi ba tloaelehileng ba ka nkela li-filter/desiccants sebaka, ha litsamaiso tsa cryogenic li hloka litsebi tse ikhethang bakeng sa ho hlokomela sehatsetsi le tora ea distillation).

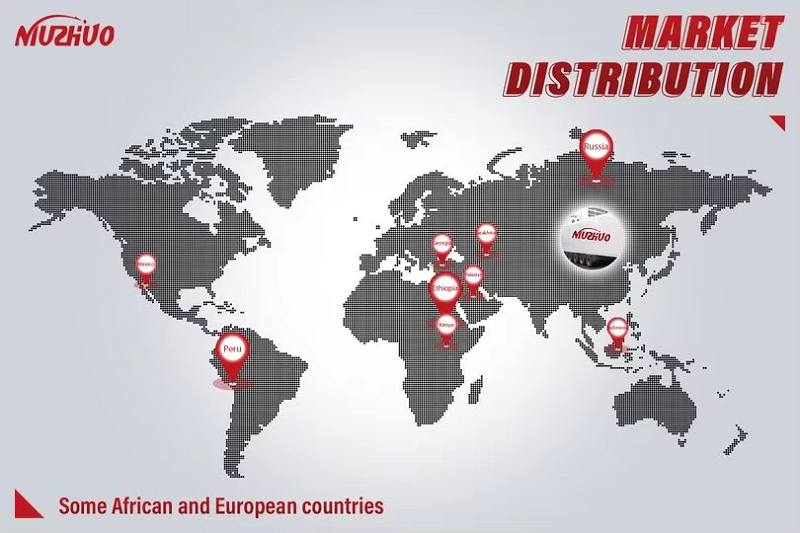

Ka boiphihlelo bo tebileng ba lilemo tse 20 indastering ea jenereithara ea naetrojene, re khoebo e kopaneng ea indasteri le khoebo e etellang pele, e kopanyang R&D, tlhahiso le thekiso ea lefats'e. Bakeng sa boleng ba sehlahisoa, re fumana thepa ea maemo a holimo: li-sefe tsa limolek'hule ho tsoa ho lihlahisoa tsa lefats'e (ho netefatsa hore ho monngoa ho tsitsitse ka lilemo tse 3-5), le likarolo tsa motlakase ho tsoa ho Siemens le Schneider (ho fokotsa sekhahla sa ho hloleha ka 80% ha ho bapisoa le likarolo tse tloaelehileng). Jenereithara e 'ngoe le e 'ngoe e feta litekong tse thata tsa 100%: ts'ebetso e tsoelang pele ea lihora tse 72 (ho etsisa maemo a 'nete a tlhahiso) le liteko tse 5 tsa bohloeki pele ho tlisoa. Tšehetso ea rona ea kamora thekiso e matla ka ho lekana: sehlopha sa baenjiniere ba nang le mangolo a 30+ se fana ka lipuisano tsa inthanete lihora tse 24/7; bakeng sa mathata a sebakeng seo, re netefatsa ho fihla nakong ea lihora tse 48 profinseng e le 'ngoe le lihora tse 72 ho pholletsa le liprofinse.

Kaha re sebeleditse dikgwebo tse fetang 2,000 ho pholletsa le diindasteri tse 12 (ho tloha dikhamphaning tsa elektroniki tsa Fortune 500 ho isa difekthering tsa dijo tsa lehae), re ikgahetse botumo ba ho tshepahala. Re amohela balekane ka mofuthu lefatsheng ka bophara bakeng sa diphapanyetsano tsa botekgeniki, dipuisano tsa ditharollo tse ikgethileng, le tshebedisano mmoho ya kgwebo—re sebetsa mmoho ho notlolla boleng ba theknoloji ya naetrojene le ho fihlella kgolo e tshwanang.

Haeba o batla ho tseba tlhahisoleseling e batsi, ka kopo ikopanye le rona ka bolokolohi:

Ikopanye le rona:Miranda Wei

Email:miranda.wei@hzazbel.com

Sehlopha/Sesebelisoa sa What's/Re qoqa:+86-13282810265

WhatsApp:+86 157 8166 4197

Nako ea poso: Phato-29-2025

Mohala: 0086-15531448603

Mohala: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com